History

More than one century of passion, determination and love for foundry work

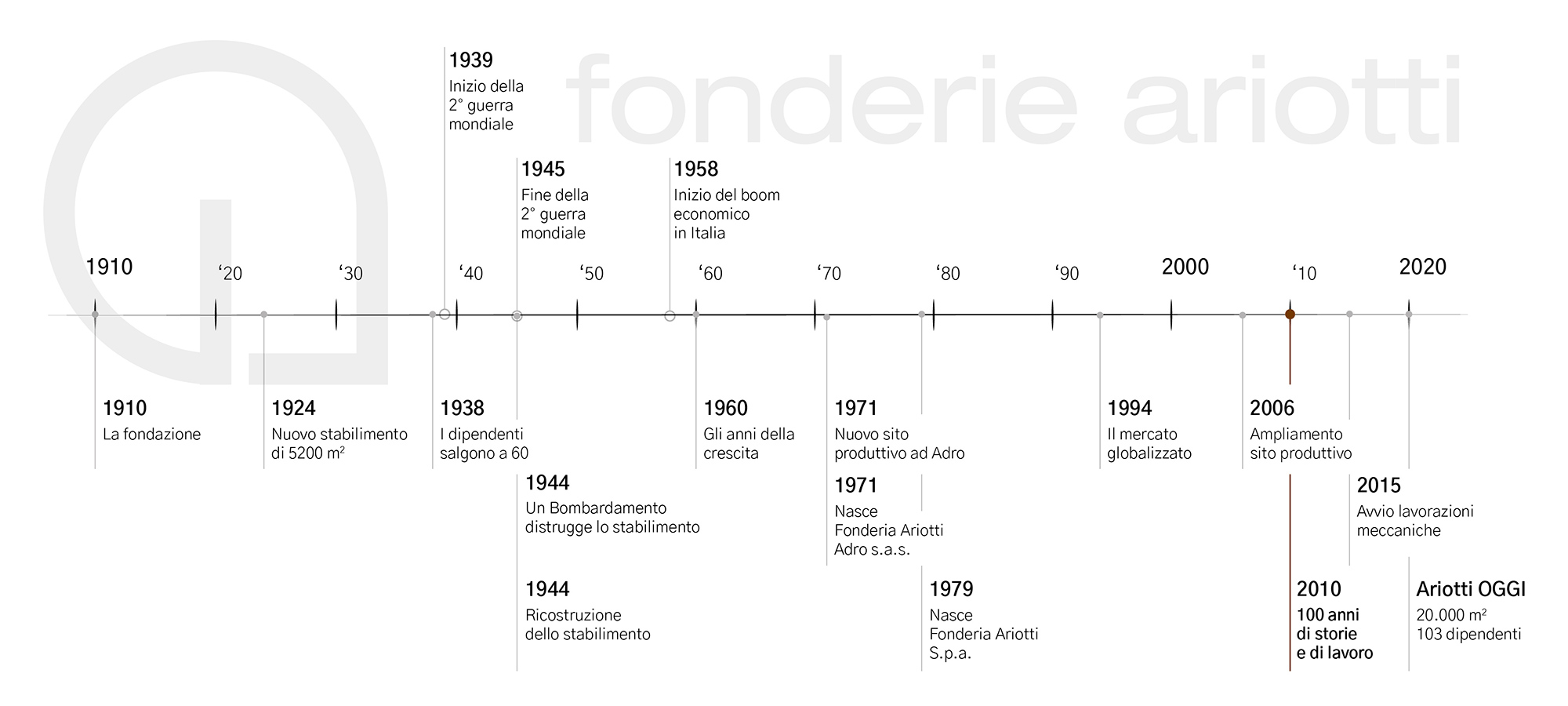

In 2020 we celebrated 110 years of history. A story about people, dreams and ambitions, but also endeavour, resistance and the ability to meet the challenges of change. Our today’s spirit is the result of many spirits which over the years have seen the evolution of a company that has grown by investing into innovation and by promoting environmental sustainability to the full.

In 2020 the company has 103 employees in its plant of approximately 20,000 covered square metres.

Historical images

1938 – Ariotti reaches 60 employees

1944 – Bombing of the plant

1944 – Reconstruction

1971 – New production site

The foundation of Fonderie Ariotti with “Nonno Pini”

1910 – 1939

Giuseppe Ariotti, known as “nonno Pini”, began the history of the foundry back in 1910. After some experience working in another foundry – Marzoli – he started his own small business in melting metals together with two of his colleagues: the Rossi brothers.

The business was initially located in a farmstead in Palazzolo Sull’Oglio and, in 1924, moved to a new 5,200 metre-squared plant close to the railway station. In the beginning, there were 35 employees, which rose to 60 in 1938.

In 1927, at the age of twenty-two, Teobaldo, Giuseppe’s son, entered the company, and towards the 1930s, in the wake of the Great Depression, father and son faced tough times, as seen in the minutes of the general meeting of 1932 for the approval of the financial statements, which read: “The ongoing drop in prices and the laborious search for work at whatever price to avoid the risk of closing the foundry due to lack of orders, has destroyed the little margin that could have been the modest and expected capital remuneration.”

The financial statement closed with a 5,798 lira loss, equal to ten percent of revenues.

1939 – 1945

The difficult war years

During the second World War, from 1939 to 1945, the foundry never stopped working. It kept going, despite the bombings, which in 1945, having the near rail bridge as aim, also hit the foundry by mistake. The only things that survived the destruction was the company car, a Fiat 1100, buried in a large wooden crate to avoid requisition by the Germans.

Mysteriously, and perhaps thanks to the longa manus of the partisan Tarzan, during a normal visit to a client, Teobaldo avoided a Nazi round-up and returned home safe and sound..On another occasion, coming back from a client on his bicycle, he avoided allied gunfire by throwing himself into a ditch by the roadside, thus succeeding in taking home not only his client’s order, but also a grenade splinter and above all, his own life.

1945 – 1960

Recovery after the war

After the end of the war, business took off again, and the foundry was rebuilt on the same site, up and running just a few months after the bombings. But there were no machines or plants and the iron was unloaded by hand from trucks. Those were the years of rebuilding and of confidence in the future. In 1957 Teobaldo’s son, Cesare Ariotti, joined the company, bringing with him innovative ideas and playing an increasingly key role in the company.

From the 1960s the country witnessed an economic, social and cultural growth. Then came the economic boom, with the Vespa, the washing machine, the fridge, mass motorisation, the transformation of a poor, farming country into an industrial power. These were also the years of workers’ demands, trade union conflicts, youth protests, the cold war, the energy crisis, terrorism and political instability.. Years that would lead to the recession and the final end of the First Republic.

1960-1990

Industrial growth

In 1971, Fonderia Ariotti Adro s.a.s. di Cesare Ariotti & C. was established, with the gradual transfer of production to the site in Adro, a completely new industrial zone, where the new factory was built on a plot of 30,000 square metres. In 1979 Fonderie Ariotti S.p.A. was established and it was a time of major transformations: the Sandslinger machine arrived to replace the working man’s shovel, and chemical moulding with self-hardening resins. Furnaces became electric, shot blasting machines arrived as well as dust collection systems.

In 1983, the foundry became affiliated with Meehanite, an English institute for metallurgic research and a quality brand for foundries. In 1986, Cesare introduced a supplementary company pension fund, twenty years before the public pension system ran into difficulty.

1990-2010

The globalised market

In 1994 and in 1997 Cesare Ariotti’s sons joined the company: Roberto and Giorgio. They began during the time of European integration, right after the devaluation of the Italian lira and the efforts of the Ciampi government which, with extraordinary financial manoeuvres, kept Italy on board the Euro train. And the foundry, just like the entire Italian production system, succeeded in finding the right way, with exchange and competition with the Germans, the Spanish and with Eastern Europe. The new company strategy was to compete by investing into high technology and quality, rather than with the low prices of developing countries. It opted for more limited series, for speedy development of prototypes, for less mature and more innovative sectors, for larger and larger castings.

In 2006, the company invested in the construction of a second factory, an underground pattern stock and a special painting area. The roof of the facilities was covered with photovoltaic panels to make the most of solar energy for production.

2010-2020

Fonderie Ariotti today

Today, the company, led by the fourth generation of the family, is a leader in its sector in terms of technology and quality, and it stands in the European market as one of the main players in large castings for the mechanical industry. It produces precision components for wind turbines, cutting machines for silicon wafers for photovoltaic cells, precision gearboxes, valves for water mains, compressors, machined plates for presses, components for huge mullers for cement. The north European market represents over 50% whose outlet is the entire world, from America to India and China.

Technology has enabled us to take giant leaps: today the design phase is carried out with the client, both in terms of geometries as well as the choice of materials and mechanical characteristics.

In 2015, Fonderie Ariotti invested in the construction of a cutting edge in-house mechanical shop, making it the first Italian technological centre in its sector, and one of the few in Europe capable of casting, machining and certifying with measuring machines the production of mechanical components for the wind power and renewable energy sector. Little more than a century after its foundation, this was a highly important step in the company’s growth, opening up to new markets and vertical integration of the industry.