An all-round service to reduce time to market

Cutting edge machining

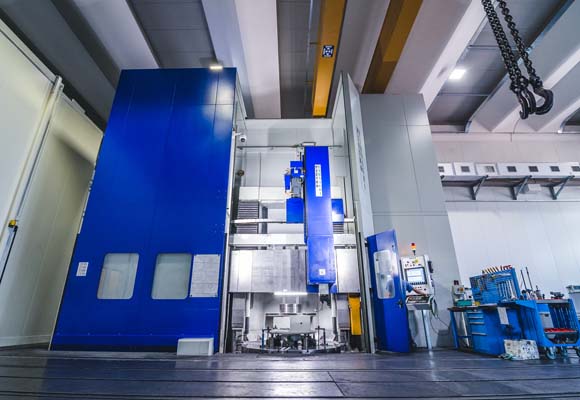

Our recently built machine shop means we can offer our clients machined castings in iron, steel and other materials on request.. We have 5-axis CNC machines with a capacity of up to 70 tons. The same building, but in an area completely temperature controlled and developed for extremely high-precision products, is equipped with a Carnaghi vertical lathe and the ZEISS measuring machine.

Thanks to our investments into these cutting edge machines we are the first Italian technological centre in the sector, and one of the few in Europe capable of casting, machining and certifying with measuring machines the production of mechanical components for the wind power and renewable energy sector.

The in-house mechanical shop at Fonderie Ariotti reduces machining times

Our mechanical shop, opened in 2015, is located in a modern building next to the foundry. The proximity between the mechanical shop and the production plants means we can quickly transfer pieces from the foundry to machining, and it allows perfect inspection before machining. To ensure a quick and efficient service for our clients, we rely on a dense network of external partners, which enable us to meet all needs and cope with production peaks, guaranteeing the flexibility that the market demands.

The service we offer is complete, quick, high quality and sustainable, thanks to the foundry-mechanical shop transfer costs saved, an expense which the client normally has to bear.

BORING AND MILLING MACHINE PAMA SPEEDRAM

BORING AND MILLING MACHINE PAMA SPEEDMAT

VERTICAL TURNING AND MILLING CENTER PIETRO CARNAGHI

VERTICAL TURNING AND MILLING CENTER DÖRRIES

VERTICAL TURNING AND MILLING CENTER SCHIESS

3D CONTROL MACHINE ZEISS MMZ-G 30 50 20